Custom Martini Glass Etching for Art Installation

A Quick Turnaround Project Story

When curator and producer Nikki Mirsaeid reached out, she had a challenge most fabrication studios avoid: etch 100–160 martini glasses with custom artwork, and deliver everything within just two weeks.

The glasses were part of a new art concept space opening in downtown Manhattan, Null Object, featuring work by artists Meriem Bennani & Orian Barki, and the engraved glassware would serve as a core element of an upcoming event.

I told them the timeline was “almost undoable”— but not impossible!

The Request: Artist-Designed Etching on Existing Glassware

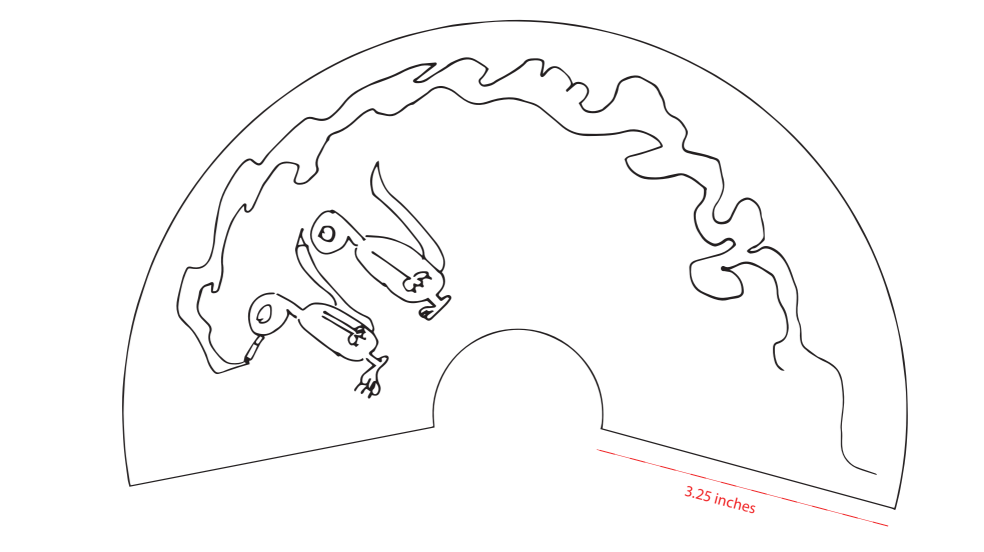

We had these drawings from Meriem, and wanted to pull out the two lizards smoking for the design on the glasses.

Nikki’s team supplied mock-ups showing possible placements on the martini glasses, and they were ready to adjust the illustrations depending on what was technically feasible on curved glass surfaces

Mock-Ups

My first step was to confirm whether we could take on the work at scale and speed. After quickly running production numbers, I provided a quote and asked for exact glass dimensions ASAP to begin plotting how the flattened artwork would wrap the conical martini-glass geometry.

Challenges of Etching on Conical Glassware

Unlike flat panels, martini glasses introduce several fabrication challenges:

Design distortion: Flat artwork must be mathematically re-shaped to avoid stretching once applied to a tapered cone.

Alignment and rotation: Each glass must be positioned consistently so the artwork sits exactly where the artists intended.

Surface clarity: Martini glass walls are thin—etching must be deep enough to read as intentional design, yet subtle enough to maintain structural integrity.

Volume production: 120+ glasses require repeatable processes, precise fixtures, and consistent quality control.

These constraints meant every step—from file preparation to final etching—had to be efficient, accurate, and bulletproof given the compressed timeline.

The Process: Engraving the Artwork Onto Glass

Once the glasses arrived, the studio prepared the designs for etching:

Artwork Conversion: The artist converted their line drawings into etch-ready vector files.

Testing on Curved Glass: Ensuring the artwork maintained its character when applied to the angled martini surface.

Fixture Setup: Creating custom supports to keep each glass perfectly level and stable during the etching process.

Etching: Using precision tools to engrave the design cleanly and consistently across more than a hundred pieces.

Final QC: Every glass was inspected for clarity, alignment, and uniformity.

The result: a collection of etched martini glasses that preserved the personality of the original drawings—clean, crisp, and fully aligned with the artists’ vision.

The Result: A Successful Delivery for Opening Week

Despite the tight schedule, we delivered a full set of custom-etched martini glasses in time for the installation’s debut in downtown Manhattan, thanks to my awesome team of collaborators.

Whether you need a single custom piece or 150+ units for a commercial or artistic installation, we’re always excited to bring ambitious glass concepts to life.

The final piece:

Keep an eye on the work from this team!